Contemporary Kiln Dried Oak Fascia Beam

Contemporary Kiln Dried Oak Fascia Beam

FREE SHIPPING

FREE SHIPPING

1 TREE PLANTED FOR EVERY £50 SPENT

1 TREE PLANTED FOR EVERY £50 SPENT

LIFETIME GUARANTEE

LIFETIME GUARANTEE

Made-to-Measure

Made-to-Measure

Dispatch estimated within 3-6 business days

Dispatch estimated within 3-6 business days

Couldn't load pickup availability

Description

Description

Opt for a sturdy kiln dried oak fascia to compliment your contemporary room...

Our kiln dried oak fascia beams are an ideal solution for those who want a very modern square design with no cracks. Our kiln dried fascia beams are 14cm x 6.5cm (5.5" x 2.5"). Manufactured from 2 pieces of oak laminated together.

When oak is kiln dried, the timber has a lower moisture content so there is less chance of any movement once installed.

Each beam comes with concealed keyhole fixings machined into the back of the beam making it ready to install. Simply hang the beam from two protruding screws in your wall. Fitting to decorated and plastered walls is no issue!

Please note: The back of the beam is left unfinished.

For a more traditional fireplace beam that will add character to your home, see our range of air dried oak beams.

Each beam we manufacturer goes through our vigorous finishing process we've developed over many years! Our kiln dried beams will be finished in your choice of stain before we apply a coat of wax.

The kiln dried fascia beam is ideal for creating the appearance of a solid built in lintel.

What you need to know

- Lifetime Guarantee!

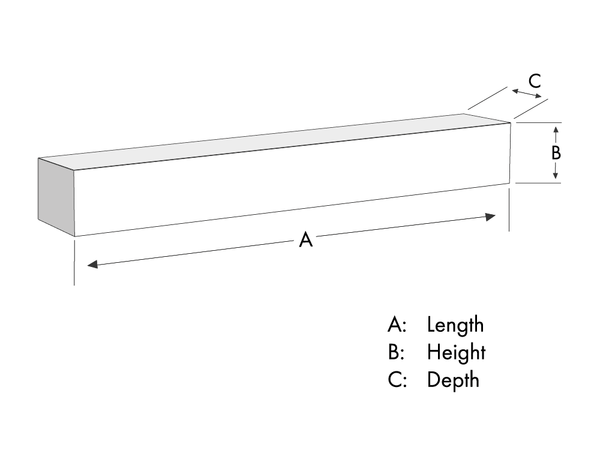

- We work to a tolerance of +/-5mm.

- Supplied with heavy duty keyhole fixings & fitting instructions.

- Kiln dried to ensure less chance of movement.

- We are a trusted online retailer – see our reviews from our past customers.

Our Timber

Our Timber

SUSTAINABILITY

We always use oak sourced from sustainably managed forests who are FSC or PEFC certified. We also plant 1 tree for every £50 spent with us. For our oak beams, this equates to planting on average 120 trees for every 1 used.

GRADING

We only use QP1 and QPA grade structural oak beams which means the angle at which the grain runs is limited, avoiding cracks to run off too severely and weakening the structure. This is equivalent to D24 or higher Construction grade.

CRACKS & MOVEMENT

Our oak beams are well air dried ensuring minimal movement once installed in your home. Read more on The importance of air dried oak. Oak beams vary in regards to cracks and splits. Cracks are a good indication of a dry beam and are part of the stunning unique features a natural oak beam has to offer. Once installed, your oak beam will start to acclimatise to room temperature. During this time cracks may change slightly, this is completely normal and will not affect the structural integrity of the beam. To minimise movement we recommend leaving your beam to acclimatise for 2 weeks prior to fitting. Once installed, gradually increase the heat of your stove over a few weeks.

OTHER DISTINGUISHING CHARACTERISTICS

Oak is a natural product, therefore knots, colour, grain pattern and other distinguishing features can vary. Some beams may have small areas of pin holing further adding to the rustic effect, we treat these beams with an anti-infestation solution.

SIZE TOLERANCE

Beam sizes are approximate to +/- 5mm. If you need a length smaller than a standard size please order the next length up and leave a note in checkout to cut it down. Please note, this will make the item non-returnable. Need something more bespoke? Get in touch for a quote.

COMBUSTIBLE MATERIAL

Oak Beams are a combustible material and should be positioned a safe distance away from heat sources in line with building and HETAS regulations. Installing a beam too close to a heat source may cause excessive cracking and be unsafe. Read more on How far above a wood burning stove can you install an oak beam.

Please note none of the above can be treated as defects.

Installation Info

Installation Info

Check out our installation guides below… Please note, all installations are different and we can only offer a general guide.

7.5″x5.5″ beams do not come with fixings.

Please Note:

We cannot take any responsibility for any incorrect installations or damage caused during the installation process. Returns are not accepted for items that have been installed.

Delivery

Delivery

Our estimated dispatch time for fireplace beams and shelves is 3-6 working days.

We use a next working day courier. Tracking details will be sent to you once your order has been dispatched.

Size Guide...

Size Guide...

OAK BEAMS

FAQ's

Do beams come with fixings?

All of our fully finished fireplace beams, with the exception of the 7.5"x5.5" size come with fixings.

Depending on the size you choose we will supply a fixing method to suit your beam...

Beams 3.5" deep or less come with heavy duty keyhole fixings pre-machined into the back of the beam.

Beams deeper than this come with our 12mm concealed fixings and pre-drilled holes.

For 7.5"x5.5" beams you can see the recommended installation method in the installation tab above.

Can I fix my beam to a plasterboard wall?

If you would like to fit solely into a plasterboard wall we recommend a beam which is 3.5" deep or less. These come with keyhole fixings and you will then be able to purchase some plasterboard specific screws and wall plugs that will work in conjunction with these.

We recommend hollow wall anchors. Alternatively if you can locate and fix into the timber studs we can change the pre-drilled hole locations to suit, enabling you to fix directly into the timber studs.

How far away from my stove can I fit my beam?

Each stove will have the safe distance to combustible materials in the manual to comply with HETAS and building regulations. The average distance is around 450mm. The beam must also be a safe distance away from the flue. This distance is usually the flue diameter x 3. You can find more information here > How far above a wood burnign stove can I install an Oak Beam.

Can I have a beam with no cracks?

Although you could specify for us to select a beam with no or minimal cracks, we can not guarantee this. It depends on the stock we have available. If we do find a beam with no cracks, we can not guarantee that it will not crack slightly once installed in a central heated home.

It is typical for air-dried beams to crack and move slightly overtime during that natural acclimatisation process to your home. Cracks are usually a good indication that the beams are well air dried. If you are looking for a beam that does not crack at all then take a look at our kiln dried oak beam.

Can I have a bespoke size?

If you would like a bespoke length, please order the next length up and leave a note in the checkout to cut the beam down.

If the length you need is longer than what is listed or you need a different section size, please contact us and we will be happy to check if this is something we can offer and provide a quote.

Please note that bespoke sizes will make the beam none-returnable.

Which side of the beam are fixings positioned?

Floating Fireplace Beams WIHTOUT corbels have the fixings positioned on one on the larger faces. Beams WITH corbels have the fixings on the smaller face.

If you need to change this just leave a note in checkout, however this will make the beam none-returnable.

Surrounds have the fixings positioned on the larger face for the uprights and the smaller face for the mantel to create an overhang.

Where does your wood come from?

In order for us to be sustainable our timber must be too! Our timber is always sourced from reliable and reputable sawmills who are FSC or PEFC certified. We also give back by planting 1 tree for every £50 spent with us.

I can't choose a size, can you help?

Yes of course, feel free to send us a message or even a photo of your fireplace and we will be happy to advise. In most cases it is just down to personal preference but smaller openings tend to suit smaller beams.